Asynchronous Geared Elevator Traction Machine THY-TM-YJ150

| Kuyimitsidwa | 1:1 |

| Max.Static Load | 3500kg |

| Kulamulira | VVVF |

| DZE-9EA Brake | Chithunzi cha DC110V 1.5A |

| Kulemera | 310kg |

1.Kutumiza Mwachangu

2.The transaction ndi chiyambi chabe, utumiki sumatha

3.Mtundu: Makina Otsitsa THY-TM-YJ150

4.Titha kupereka makina a synchronous ndi asynchronous traction a TORINDRIVE, MONADRIVE, MONTANARI, FAXI, SYLG ndi mitundu ina.

5.Kukhulupirira ndi chisangalalo! Sindidzalephera kudalira kwanu!

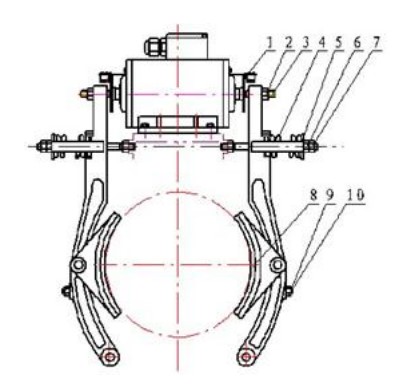

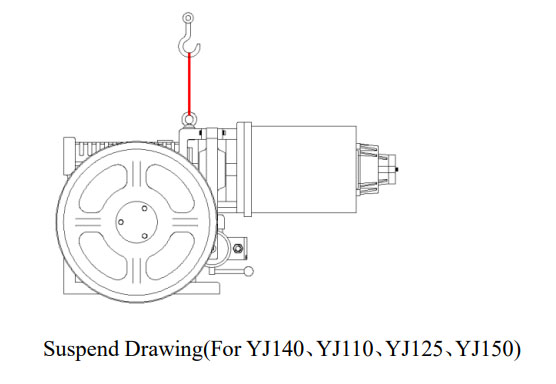

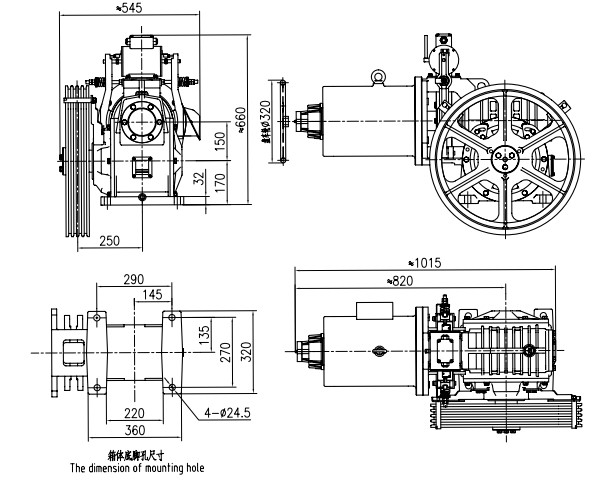

THY-TM-YJ150 yoyendetsedwa ndi asynchronous elevator traction makina imagwirizana ndi TSG T7007-2016, GB 7588-2003, TS EN 81-20: 2014 Malamulo achitetezo pomanga ndi kuyika zokwezeka - Zokwera zonyamula anthu ndi katundu - Gawo 20: 81-50: 2014 Malamulo a chitetezo pomanga ndi kuyika zokwezera -Kuyesa ndi mayesero -Gawo 50: Malamulo opangira, kuwerengera, mayeso ndi mayesero a zigawo zokweza. Mtundu wa brake wofanana ndi makina okokera ndi DZE-9EA. Ndi oyenera katundu chikepe ndi katundu mphamvu 500KG ~ 750KG. Imatengera mtundu wochepetsera wa nyongolotsi. Zida za nyongolotsi ndi 40Cr ndipo gudumu la nyongolotsi ndi ZQSn12-2. Makinawa ali okwera bwino komanso okwera kumanzere akupezeka.Galasi yamafuta yomwe timalimbikitsa ndi Shell Omala S2 G460 kapena mafuta ofananirako kalasi ya viscosity grade, YJ150 (motor ≥10KW) yodzazidwa ndi mafuta opangira 460. Makina okokera amakhala ndi makina otulutsa mabuleki, omwe amagwiritsidwa ntchito kusuntha pamanja galimoto pamene chikepe chikulephera. Ndizoletsedwa kugwiritsa ntchito muzochitika zomwe sizili zadzidzidzi. Oyenera malo ogwirira ntchito m'nyumba.

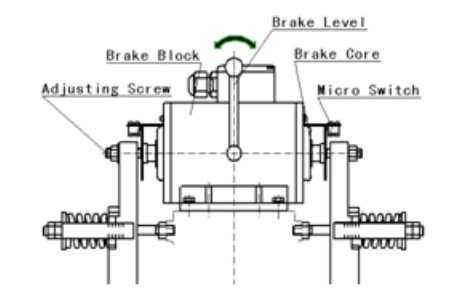

1. Ikani wrench yotulutsa mabuleki ku brake;

2. Tembenuzirani chowongolera cha brake mbali iliyonse kuti mutulutse brake.

1. Kusintha kwa mphamvu ya braking: Masulani nati 6 ndi nati 7 pa mapeto aakulu a kasupe kuti kasupe akhale womasuka, kukoka mtedza 6 kuti apange kapu ya kasupe 5 abut motsutsana ndi mapeto a masika, landirani mphamvu pang'ono, ndikutembenuzirani mtedzawo mozungulira 6 Pezani mphamvu yokwanira yoboola, ndiyeno kumangitsa ndi mtedza 7.

2. Kusintha kwa nsapato ya brake: dongosolo la brake lili mu chikhalidwe chogwira mabuleki. Pamene kuthamanga kwa kasupe kumapanga mphamvu yokwanira yopondereza mkono wa brake, arc pamwamba pa nsapato ya brake ili pafupi ndi arc pamwamba pa gudumu la brake. Panthawiyi, sinthani kumapeto kwa nsapato ya brake. 9 ya screw kuti screw ingokhala kumapeto kwenikweni kwa nsapato ya brake. Mabuleki akapatsidwa mphamvu kuti amasule brake, tembenuzirani wononga 9 molunjika, ndipo gwiritsani ntchito geji yoyezera kuti muyeze kusiyana pakati pa nsapato ya brake ndi malo awiri opindika a gudumu la brake. Mpata ukasinthidwa kuti ukhale mmwamba ndi pansi, gwiritsani ntchito nati 10 kutseka wononga.

3. Kusintha kwa phokoso lotsegula: masulani nati 2, limbitsani phokoso, muyese kusiyana pakati pa nsapato ya brake 8 ndi malo awiri a arc a gudumu la brake ndi geji yomveka mutatha kutsegula, ndikuwonetsetsa kuti kusiyana pakati pa nsapato ya brake ndi malo awiri a arc a gudumu la brake ndi 0.2mm kuonetsetsa kuti pali 0. palibe kukangana pakati pa nsapato ya brake ndi gudumu la brake potsegula brake). Pamene kusiyana kotsegulako kuli kochepa kwambiri, screw 3 iyenera kutembenuzidwa motsatira wotchi kuti muchepetse kusiyana pakati pa screw 3 ndi cap cap, ndi mosemphanitsa kuti muwonjezere kusiyana. Mukasinthidwa pamalo oyenera, gwiritsani ntchito nut 2 kuti mutseke screw 3 mwamphamvu. Yang'ananinso ngati sitiroko yopanda pake ya brake ikukwaniritsa zofunikira.

4. Kusintha kwa kulunzanitsa kwa brake kutsegula: kuyatsa ndi kuzimitsa mphamvu ya brake ndikuwona kulumikizika kwa mkono wa brake potsegula chiboliboli. Pamene mbali imodzi imathamanga ndipo mbali ina ikuchedwa, ngati phokoso la braking liri lokwanira, kutha kwapang'onopang'ono kudzafupikitsa ntchito ya brake Stroke (kumasula wononga), m'malo mwake, mapeto othamanga amawonjezera kuphulika kwa brake (kulimbitsa wononga). Sinthani pamene mukuyang'ana, ndi kutseka mtedzawo mpaka utagwirizanitsidwa. Yang'ananinso ngati sitiroko yopanda pake ya brake ikukwaniritsa zofunikira. Pambuyo pakusintha, fufuzani ngati mbali zolumikizidwa ndi zokhoma zatsekedwa, ndikuyesa mayeso a braking force kapena elevator static load test.